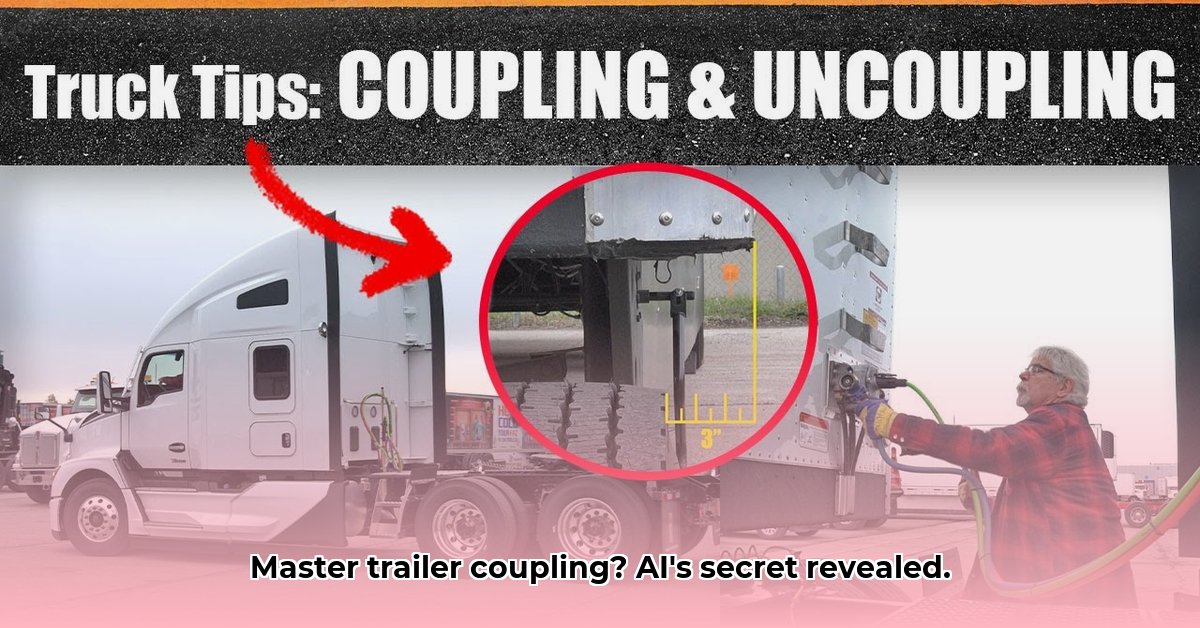

Coupling System Tractor Trailer: Mastering the A.I.M. Method for Safety

Hitting the road with a tractor-trailer requires more than driving skill; safe and efficient coupling is paramount. A properly coupled rig operates smoothly and safely, while a poorly coupled one poses significant risks. This guide details the A.I.M. (Align, Insert, Make Secure) and D.R.O.P. (Disconnect, Release, Observe, Pull) methods, emphasizing safety at each step.

For more details on fifth wheel coupling, see this helpful resource: Fifth Wheel Information.

Did you know that improper coupling accounts for a significant percentage of trucking accidents? This guide helps mitigate that risk.

Pre-Coupling Inspection: Your Safety Checklist

Before coupling, a thorough inspection is crucial. This prevents accidents and costly downtime. Think of it as a pre-flight check for pilots—essential for safety.

Fifth Wheel Fitness: Inspect the fifth wheel for damage, cracks, or wear. Ensure the locking mechanism functions smoothly and the kingpin is lubricated.

Landing Gear Lowdown: Confirm the trailer's landing gear is fully retracted and locked. A partially extended gear creates an unstable connection.

Lighting Check: Test all trailer lights (brake lights, running lights, turn signals) to ensure functionality. Faulty lights are a significant safety hazard.

Air and Electrical Connections: Inspect air lines for damage or leaks, and electrical connections for security and integrity. Leaks can impact braking, while faulty electrical connections can disable safety features.

Brake Test: Manually test the trailer's brakes before coupling. This step is non-negotiable for safety.

Visual Scan: Perform a visual inspection of the trailer for any damage, loose parts, or irregularities.

Coupling Procedures: The A.I.M. Method for Success

The A.I.M. method is a proven approach to safe coupling.

A – Align: Carefully position the tractor so the fifth wheel is directly over the trailer's kingpin. Precise alignment is crucial to prevent damage.

I – Insert: Slowly back the tractor until the kingpin smoothly slides into the fifth wheel. Avoid jerky movements.

M – Make Secure: Once the kingpin is fully seated, firmly engage the locking mechanism. Always double-check manually.

Post-Coupling Checks: Double-Checking Your Work

After coupling, several critical checks are necessary:

Kingpin Confirmation: Verify the kingpin is fully seated and the locking mechanism is engaged.

Brake Systems Check: Conduct another brake test to ensure proper functionality after coupling.

Air Pressure Check: Check the trailer's air pressure; sufficient pressure is vital for safe braking.

Repeat Lighting Check: Re-test all lights and signals.

Final Visual Inspection: Perform another visual check of the connection.

Uncoupling Procedures: The D.R.O.P. Method

The D.R.O.P. method ensures safe uncoupling.

D – Disconnect: Carefully disconnect air and electrical lines.

R – Release: Carefully release the fifth wheel locking mechanism.

O – Observe: Observe the connection point as you slowly pull away.

P – Pull: Slowly pull away, ensuring the trailer is stable and lower the landing gear.

Post-Uncoupling Checks: Final Verification

After uncoupling, verify these steps:

Confirm air and electrical connections are safely disconnected and stowed.

Ensure the trailer's landing gear is fully extended and secure.

Troubleshooting Common Problems

Here are solutions to common coupling/uncoupling issues:

| Problem | Solution |

|---|---|

| Kingpin Misalignment | Carefully reposition the tractor; use leveling blocks if needed. |

| Locking Mechanism Failure | Inspect for debris or damage. Repair or replace faulty components. |

| Air Line Leaks | Repair or replace damaged lines; tighten connections. |

| Electrical Issues | Inspect wiring; tighten connections; replace damaged components. |

Safety Considerations and Best Practices

Weight Distribution: Proper weight distribution prevents handling issues and accidents.

Load Securing: Secure cargo to prevent shifting and hazards.

Regular Maintenance: Regular maintenance prevents unexpected failures.

Driver Training: Ongoing training reinforces safe coupling procedures.

Key Takeaways:

- Thorough pre-coupling inspections are crucial for safety.

- Mastering the A.I.M. method ensures safe coupling.

- Post-coupling checks prevent mishaps.

- Using the D.R.O.P. method for uncoupling is vital.

- Regular maintenance and driver training minimize risks.

How to Prevent Tractor Trailer Coupling Accidents

Remember, consistent adherence to these procedures and a prioritization of safety are essential for safe and efficient operation. Following these steps significantly reduces the risk of accidents and ensures many years of safe driving.